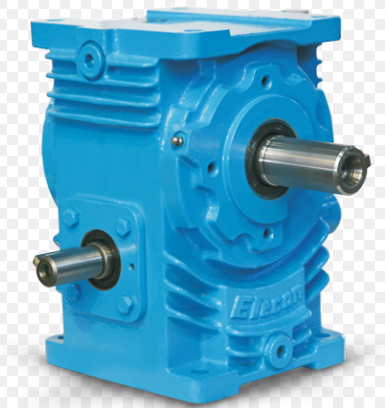

Their unusual design and function make worm gearbox vital parts in several industrial uses. Ideal for equipment that needs exact control, these gear systems enable smooth operation and effective torque transmission. The unique quality of a worm gearbox is its capacity to offer great reduction ratios in a small design. Allowing for more torque output not only saves space but also improves the performance of equipment. From conveyor systems to automotive equipment, their adaptability makes them appropriate for a wide spectrum of uses, so guaranteeing that businesses run more efficiently and effectively.

Small Design for Space Efficiency

Their small size, which makes them ideal for use where the space is limited, is one of the most remarkable properties of the worm gearbox. Unlike traditional gear systems, a worm gearbox can result in a significant reduction in a small footprint. In limited areas where large gear systems will be unhealthy, it is very useful. Folding these gearboxes into small places creates more flexible design options in machines. The small size of the worm gearbox provides a reasonable answer that satisfies both space and performance as companies are looking for ways to maximize the layout.

Great Load Capacity and Torque

Worm gears are well known for their capacity to properly manage large torque loads. A worm gear’s design provides a notable mechanical advantage. Thus, even little inputs can generate considerable outputs. This is especially true for applications needing great force and large machines. A worm gearbox’s high load capacity guarantees that it can endure trying circumstances without sacrificing performance. In industries like manufacturing, construction, and mining, where the demands on equipment can be severe, this capacity is absolutely vital. Consequently, several sectors’ productivity and dependability are much improved by these gearboxes.

Minimal Maintenance Needs

The Worm gearbox has reduced the need for maintenance, which is another great advantage. Their design allows these gear systems to run smoothly and with low friction, which reduces wear over time. This facility allows companies to reduce maintenance expenses and shutdowns so that the equipment can run more regularly. For companies that want to invest in reliable devices, the life and durability of a worm gearbox make it a desirable alternative. Choosing gearboxes, which require less regular service, helps companies focus on the main activities instead of wasting time on maintenance and repair.

Versatility in Various Sectors

Worm boxes are used in many different regions and show the ability to adapt. From food processing to a motor vehicle, these gear systems can meet different operating requirements. His ability to work well in many surroundings makes him qualified as a great advantage for companies. Special use, such as robotics and automation, shows how a worm gearbox fits into modern technology. Verm Gearbox is ideal for meeting these needs when business changes and the need for flexible and effective gear systems is increasing.

Improved Safety Aspects

In industrial applications, security comes first; Worm boxes help to promote safe operations. Their design closes natural back driving, so the entrance will be closed, and the output will not move on. In contexts where unexpected movement can cause dangerous conditions, this task is absolutely important. The inclusion of a worm gearbox in the machinery helps manufacturers improve reliability and low accident risk. In high-load settings and fast speed, this addiction is especially important because it guarantees that operators safely operate the devices they use.

Conclusion:

Worm Gearbox provides a clear advantage in many industrial applications. Their small size, large torque capacity, cheap maintenance requirements, and adaptability make them perfect for different industries. Worm Gearbox will have a basis for modern machines when businesses change and look for effective solutions. The discovery of Australia-drve.com can offer useful ideas and answers to include these creative equipment systems for those who want to improve these creative gear systems to improve operating efficiency.